Umgangatho we-PVC uxhaphake kakhulu kwi-ofisi yokuhombisa yanamhlanje, kunye neenzuzo zokungangeni kwamanzi, ukuvutha umlilo, ukuthulisa, njl.

1. Galela umxube we-self leveling slurry kumgangatho wokwakha, uya kuhamba kwaye ulungelelanise umhlaba ngokwawo.Ukuba ubukhulu boyilo bungaphantsi okanye bulingana ne-4mm, kufuneka kusetyenziswe i-scraper ekhethekileyo yamazinyo ukukhuhla kancinci.

2. Emva koko, abasebenzi bokwakha baya kufaka izicathulo ezikhethekileyo ze-spiked kwaye bangene kumhlaba wokwakha.Isilinda somoya esikhethekileyo esizilinganisa ngokwaso siya kusetyenziswa ukuqengqeleka ngobunono kumphezulu wokuzilinganisa ukukhulula umoya oxutywe kumxube, ukuze kuthintelwe iqamza eliphawulweyo lomphezulu kunye nomahluko wobude bojongano.

3. Nceda uvale isiza ngokukhawuleza emva kokugqitywa kokwakhiwa, thintela ukuhamba kwiiyure ezi-5, uthintele ukungqubana kwezinto ezinzima kwiiyure ezili-10, kwaye ubeke umgangatho wePVC emva kweeyure ezingama-24.

4. Kulwakhiwo lwasebusika, umgangatho uya kubekwa kwiiyure ezingama-48-72 emva kokwakhiwa kokuzilinganisa.

5. Ukuba kuyimfuneko ukugqiba ukupholisa i-self leveling, kufuneka iqhutywe emva kokuba i-samente yokuzimela yome ngokupheleleyo.

Ukuhlolwa kweemeko zokwakha

1. Sebenzisa imitha yobushushu kunye nokufuma ukubona iqondo lobushushu kunye nokufuma.Ubushushu bangaphakathi kunye nobushushu bomhlaba kufuneka bube yi-15 ℃, endaweni yolwakhiwo lube ngaphantsi kwe-5 ℃ nangaphezulu kwe-30 ℃.Ukufuma komoya okunxulumeneyo okulungeleyo ukwakhiwa kuya kuba phakathi kwe-20% kunye ne-75%.

2. Ubumanzi bekhosi yesiseko buya kuvavanywa ngumvavanyi wobumanzi, kwaye umxholo wokufuma kwikhosi yesiseko uya kuba ngaphantsi kwe-3%.

3. Amandla ekhosi yesiseko akayi kuba ngaphantsi kweemfuno zamandla ekhonkrithi C-20, ngaphandle koko ukuzilinganisa okufanelekileyo kuya kwamkelwa ukuqinisa amandla.

4. Iziphumo zovavanyo kunye ne-hardness tester iya kuba kukuba ubunzima bomphezulu wekhosi abuyi kuba ngaphantsi kwe-1.2 MPa.

5. Ukwakhiwa kwezinto zomgangatho, ukungalingani kwekhosi yesiseko kuya kuba ngaphantsi kwe-2mm ngaphakathi kwe-2m edge eqondileyo, ngaphandle koko, ukulinganisa okufanelekileyo kuya kwamkelwa ukulinganisa.

Ukucoca umphezulu

1. Sebenzisa isixhobo sokusila somgangatho esingaphezu kweewathi ezili-1000 kunye neziqwenga ezifanelekileyo zokusila ukugudisa umgangatho uphela, susa ipeyinti, iglu kunye nezinye iintsalela, umhlaba onamaqhuqhuva kunye nomhlaba othe tyaba, nomhlaba ongenanto nawo kufuneka ususwe.

2. Umgangatho uya kucocwa ngevacuum cleaner engekho ngaphantsi kwe 2000 Watts.

3. Ukuqhekeka emgangathweni, i-stiffeners yensimbi engenasici kunye ne-polyurethane yokunamathela emanzini ingasetyenziselwa ukukhanda isanti ye-quartz phezu komhlaba ukuze kulungiswe.

Ulwakhiwo lwe-arhente ye-interface

1. Ikhosi ye-absorbent base, efana nekhonkrithi, i-cement mortar kunye ne-level layering layer, iya kutywinwa kwaye igxininiswe nge-arhente yonyango ye-interface ye-multi-purpose kunye namanzi kumlinganiselo we-1: 1.

2. Kwikhosi yesiseko engasiyo i-absorbent, efana nethayile ye-ceramic, i-terrazzo, i-marble, njl., kuyacetyiswa ukuba usebenzise i-arhente yonyango ye-dense interface kwi- bottoming.

3. Ukuba umgangatho womswakama wekhosi yesiseko uphezulu kakhulu (> 3%) kwaye ulwakhiwo kufuneka luqhutywe ngokukhawuleza, i-epoxy interface yonyango ye-epoxy ingasetyenziselwa unyango lwe-priming, ngaphandle kokuba umgangatho womswakama wekhosi yesiseko. hayi ngaphezulu kwe-8%.

4. I-arhente yonyango ye-interface isetyenziswe ngokulinganayo ngaphandle kokuqokelela okucacileyo kolwelo.Emva kokuba umphezulu we-ejenti yonyango ye-interface yomiswe ngomoya, ukwakhiwa okulandelayo kokuzilinganisa kunokuqhutywa.

Umlinganiselo wokuzilinganisa

1. Galela ipakethe ye-self leveling kwibhakethi yokuxuba ezaliswe ngamanzi acacileyo ngokomlinganiselo ochaziweyo wesamente yamanzi, kwaye uthele kwaye udibanise ngexesha elifanayo.

2. Ukuze kuqinisekiswe ukuba kunye nokudibanisa ukulinganisa, kuyimfuneko ukusebenzisa i-high-power, i-low-speed drill yombane kunye nomxube okhethekileyo wokuxuba.

3.S tir kwi-slurry efanayo ngaphandle kwe-caking, vumela ukuba ume kwaye uvuthwe malunga nemizuzu emi-3, kwaye uvuselele kwakhona ngokufutshane.

4. Ubungakanani bamanzi abongeziweyo luya kuhambelana ngokungqongqo kunye nomlinganiselo wesamente yamanzi (nceda ubhekisele kwimiyalelo ehambelanayo yokuzilinganisa).Amanzi amancinci kakhulu aya kuchaphazela ukumanzi, kakhulu kuya kunciphisa amandla emva kokunyanga.

Ulwakhiwo lokuzilinganisa

1. Galela umxube we-self leveling slurry kumgangatho wokwakha, uya kuhamba kwaye ulungelelanise umhlaba ngokwawo.Ukuba ubukhulu boyilo bungaphantsi okanye bulingana ne-4mm, kufuneka kusetyenziswe i-scraper ekhethekileyo yamazinyo ukukhuhla kancinci.

2. Emva koko, abasebenzi bokwakha baya kunxiba izihlangu ezikhethekileyo ezine-spiked, bangene kumhlaba wokwakha, basebenzise isilinda esikhethekileyo somoya ukuqengqeleka ngobunono kumphezulu wokuzilinganisa, ukukhulula umoya oxutywe kumxube, kwaye unqande i-bubble ephawulweyo kwindawo kunye nojongano. umahluko ubude.

3. Nceda uvale isiza ngokukhawuleza emva kokugqitywa kokwakhiwa, ungahambi kwiiyure ze-5, ugweme impembelelo yento enzima kwiiyure ze-10, kwaye ubeke umgangatho emva kweeyure ezingama-24.

4. Kulwakhiwo lwasebusika, umgangatho uya kubekwa iiyure ezingama-48 emva kokuzilinganisa.

5. Ukuba kuyimfuneko ukugqiba ukupholisa i-self leveling, kufuneka iqhutywe kwiiyure ezili-12 emva kokwakhiwa kokuzilinganisa.

Ukupeyinta kwangaphambili

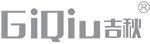

1. Zombini izixhobo ze-coil kunye nebhloko ziya kufakwa kwisiza ngaphezu kweeyure ezingama-24 ukubuyisela inkumbulo yezinto kunye nokugcina ubushushu buhambelana nendawo yokwakha.

2. Sebenzisa isixhobo sokucheba esikhethekileyo ukusika kunye nokucoca umgca orhabaxa wekhoyili.

3. Xa ubeka iibhloko, kufuneka kungabikho ukujoyina phakathi kweebhloko ezimbini.

4. Xa ubeka izinto ezidibeneyo, ukugqithwa kwezinto ezimbini zezinto eziphathekayo kuya kunqunyulwa ngokugqithiswa, okufunekayo ngokubanzi ukuba kugqitywe nge-3cm.Nika ingqalelo ukugcina imela enye isikiwe.

Gluing

1. Khetha i-glue efanelekileyo kunye ne-rubber scraper emgangathweni ngokuhambelana nobudlelwane obuhambelana neetafile ezixhasayo kwesi sikhokelo.

2. Xa i-coiled material ifakwe, isiphelo sezinto ezidibeneyo ziya kugotywa.Okokuqala ucoce umgangatho kunye nomva we-roll, uze udibanise iglue phantsi.

3. Xa uvula ibhloko, nceda ujike ibhloko ukusuka phakathi ukuya kumacala omabini, kwaye kwakhona uhlambulule umhlaba kunye nomgangatho ophantsi kwaye unamathisele ngeglue.

4. I-adhesives eyahlukeneyo iya kuba neemfuno ezahlukeneyo ekwakhiweni.Nceda ubhekisele kwimiyalelo yemveliso ehambelanayo yokwakhiwa.

Ukubeka kunye nokufakwa

1. Emva kokuba umgangatho uncanyathiselwe, tyhala kuqala kwaye ucinezele umgangatho womgangatho ngebhloko yeplanga elithambileyo ukuya kwinqanaba kwaye ukhuphe umoya.

2. Emva koko sebenzisa i-50 okanye i-75 kg ye-roller yensimbi ukuze uqhube umgangatho ngokulinganayo kwaye unqande i-edge edge ye-joint ngexesha.

3. Iglue engaphezulu kwinqanaba lomgangatho kufuneka licinywe ngexesha.

4. Emva kweeyure ezingama-24, inotshi kwaye weld kwakhona.

Slotting

1. I-Slotting kufuneka iqhutywe emva kokuba iglue iqiniswe ngokupheleleyo.Sebenzisa i-slotter ekhethekileyo yokubeka ecaleni kwendawo edibeneyo.Ukuze wenze i-welding iqine, i-slotting ayiyi kungena ngaphantsi.Kucetyiswa ukuba ubunzulu be-slotting bube yi-2/3 yobukhulu bomgangatho.

2. Ekupheleni apho i-seamer ingenako ukusika, nceda usebenzise i-seamer ye-manual ukusika ubunzulu kunye nobubanzi obufanayo.

3. Ngaphambi kwe-welding, uthuli oluseleyo kunye ne-debris kwi-groove iya kususwa.

Ukuwelda

1. Umpu we-welding manual okanye izixhobo ze-welding ezizenzekelayo zingasetyenziselwa ukudibanisa.

2. Ubushushu bompu we-welding kufuneka bubekwe malunga ne-350 ℃.

3. Cinezela i-electrode kwi-groove evuliwe kwisantya esifanelekileyo se-welding (ukuqinisekisa ukunyibilika kwe-electrode).

4. Xa i-electrode iphelile isiqingatha, sebenzisa i-electrode leveler okanye i-cutter yenyanga ukusika ngokukhawuleza indawo apho i-electrode iphezulu kune-floor plane.

5. Xa i-electrode ipholile ngokupheleleyo, sebenzisa i-electrode leveler okanye i-cutter yenyanga ukusika inxalenye eseleyo ye-convex ye-electrode.

Ixesha lokuposa: Jan-20-2021